When it comes to power tools, sanders are incredible tools that are perfect for polishing wood or smoothing out surfaces on a variety of materials. Since angle grinders have changeable discs for different types of use, can an angle grinder be used as a sander?

An angle grinder can be used as a sander if the disc on the grinder is made specifically for sanding. With the high velocity of speed that comes with using an angle grinder, a sanding disc can do twice the sanding capabilities in a shorter amount of time than a traditional sander.

You are probably familiar with hearing about cutting and grinding when you hear about angle grinders. Therefore, this article will explore the sanding capabilities of an angle grinder and more frequently asked questions.

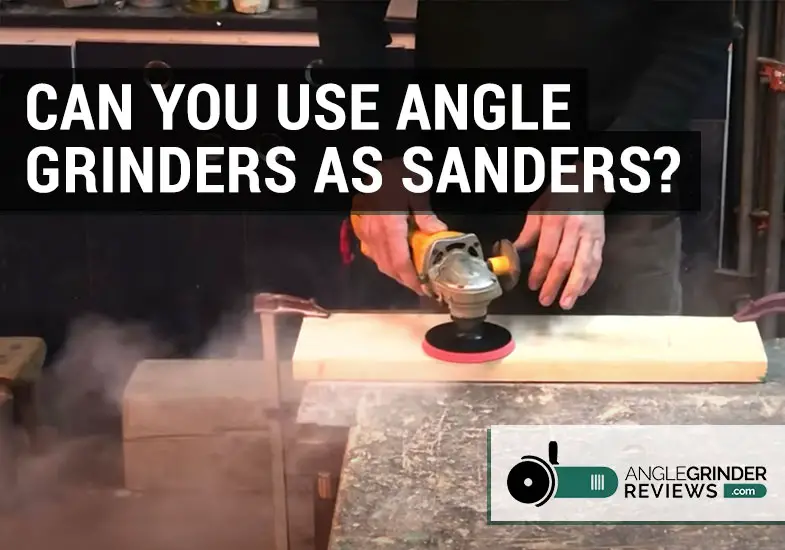

Before we begin, take a look at this video which shows how an angle grinder can be used to effectively sand wood surfaces:

Using an Angle Grinder For Sanding

A sander is a power tool that uses sandpaper belts to that rotate at high speeds along with a belt sander. The most common type of sander you will typically find is known as a belt sander, which moves around a pair of drums at high speed to effectively polish or ‘sand’ a surface – usually wood.

Sanders are always good additions to have in your tool arsenal, but an angle grinder can do the same job with what will likely produce better results in the long run. Angle grinders are versatile, which means that you can purchase sanding discs that are specifically designed only for sanding.

These angle grinder attachments are known as flap discs, which have a wide range of uses including smooth finishing on a surface that needs to be smoothed over. Sanding discs when paired with angle grinders can go far beyond simple sanding on wood surfaces.

Flap discs can strip paint from metal at the most powerful end or, simply smooth over a surface like wood which is the same use you would get out of belt sanders.

With this in mind, choosing the right kinds of flap discs when using angle grinders for sanding is crucial to avoid having a rough and abrasive surface. Let’s explore some types of flap discs that you should use with a grinding tool when sanding:

No products found.

S-SATC High-Density Angle Grinder Sanding Disc

This incredibly smooth and versatile disc is perfect for sanding wood or polishing metal. This disc set comes with 20 flap discs and is constructed of industrial-grade high-density premium zirconia material; featuring more increased durability than standard flap discs, which makes for a more robust and economical grinding wheel.

Coceca Sanding Grinding Wheels

When it comes to working with wood, grinder vs sander is the choice most people find themselves trying to make. An angle grinder needs a quality disc with quality sandpaper and Coceca is one company that specializes in discs that mimic the effect of belt sanders.

This 20-pack set of sanding discs are perfect for sanding either wood or metal and make the work involved a breeze due to the ridged sandpaper discs.

Is a Grinder the Same as a Sander?

Angle grinders are a versatile power tool but these tools are not the exact same as a sander. A grinder is primarily used to grind thick materials such as metal.

Grinding is not like sanding; grinding involves stripping thick material without resorting to cutting or damaging the material. In other words, grinding is more about shrinking an object slowly and with precision.

Sanding is all about the process of smoothing and polishing material to create a fine, non-abrasive surface.

Therefore, a grinder is geared towards reducing thick material that doesn’t give much resistance and a sander is aimed towards smoothing out the rough exterior.

A grinder can be used as a sander whereas a sander cannot necessarily be used to grind material.

Can You Put a Wood Blade on an Angle Grinder?

It is not usually not recommended to use a grinding tool to cut wood, however, there are blades that can be attached to use specifically on wood.

Wood blades typically need to have teeth within the disc to provide some resistance to the high speed that comes when you work with grinders. With this in mind, even when you use a wood-cutting blade when you work, a face shield and safety glasses are recommended to avoid a large amount of debris that will come from sawing into the wood.

Additionally, a grinding tool will need to be closely monitored when you use it to cut wood to avoid possible injuries that could arise from using a tool that is meant for metal and stone on a thinner material such as wood.

Frequently Asked Questions

What Can an Angle Grinder Be Used For?

A grinding tool can be used for a variety of tasks, such as grinding and sanding, and for construction tasks, such as cutting and shaping stones. A well-built product will help you perform cutting edge and demanding jobs, such as cutting cement or stucco.

A grinding tool provides a great way to work with stubborn materials that do not respond to traditional cutting or edging methods. The right tool will help you perform a variety of grinding, cutting, and polishing jobs with ease.

Always opt for a versatile machine that features multiple attachments and accessories. This will allow you to perform a variety of jobs with minimal efforts.

The ideal grinding tool is not only able to sharpen and grind objects efficiently but is also lightweight and not too bulky, which offers you maximum control when using one of the most powerful tools in the hardware market.

See our post on using an angle grinder as a polisher.

Can an Angle Grinder Be Used as a Cut Off Tool?

A cut-off tool is a great go-to option when you need to cut materials quickly and efficiently; however, an angle grinder can do the same if you use a cutting blade, in addition to providing sanding, polishing, and grinding that a cut-off tool cannot accomplish.

A cut-off tool is best-suited for use on smaller materials that typically do not exceed 3-4 inches in length. This is because the cut-off tool is perfect for making precise cuts in smaller measures.

A disc can make bold and large cuts due to the strong release of energy and pressure but the angle grinder is not perfect for smaller materials or for making lots of detail in your cutting procedure. An angle grinder works better on new materials, such as sheet metal, because the cut will be clean and sharp, whereas a cut-off tool makes more rugged cuts.

For example, if you use an angle grinder to grind metal or stone, this is not possible with a cut-off tool since the precision is sharp and lacking in angles and smooth turns that come with using an angle grinder disc to make cuts.

If you need to make more details in your cutting, the bulky spinning motion of an angle grinder is not going to work so well and its use should be limited to large and open projects that need to be done quickly. A cut-off tool allows you to make a series of cuts in quick succession with the ability to modify various types of cuts.

Conclusion

Sanding can certainly be achieved with an angle grinder and you simply need to change the disc to a sanding disc whenever you want to create a smoother surface to any material. Working with wood surfaces is going to be much easier with a regular sander since wood is the only surface meant to be sanded with a traditional sanding tool.

As far as which is best, you will certainly have a variety of different uses when you use a grinding tool than what you can achieve with a traditional sander. But having both tools in your toolkit is not a bad option since both tools are great depending on the material you need to work with.